Assembly and Test Facility for Dynamic Light Systems

Thinking ahead – for the right lighting mood

More than ambient light

Dynamic Light is an innovative light band developed by a premium car manufacturer, used primarily in their high-end models where it runs the full length of the interior. Not only can it create specific lighting moods within the vehicle; it also conveys relevant safety information. For example, the blind spot assistant plays a red-light animation to alert the driver to a potential collision. The light band consists of numerous LEDs placed next to each other and is invisible while inactive. Dynamic Light activates a strip of light. Each LED is controlled in real time. This allows for seamless displays, smooth transitions and, in a world first, color gradients in addition to single colors.

We love to explore!

Whenever a fascinating new technology for high-end cars emerges, our testing experts are sure to be involved. For all our experience in a wide variety of projects, our engineers are still excited by novelty and the unknown.

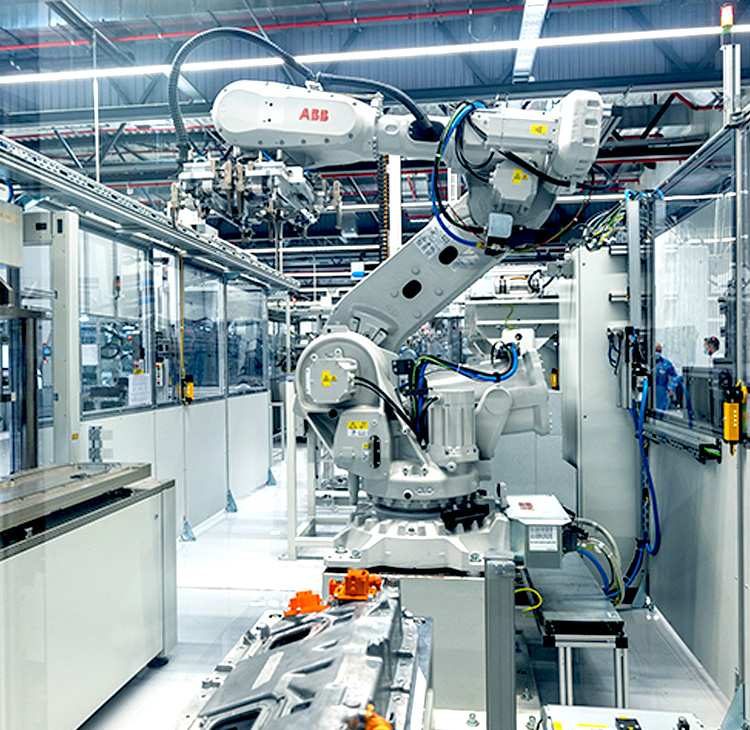

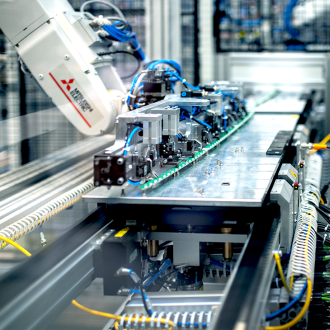

This was the case for the Dynamic Light system, which requires handling unusually long plastic components. Individual circuit boards are press-fitted with connecting elements. This is done with a specific force, which we monitor in production using force-displacement measurement, to ensure that the connections do not come loose from the vibrations when the vehicle is driving.

Completely clean thanks to AI

We at MARQ4 Automation are always intrigued by new technologies. They challenge us to utilize all our engineering expertise to make something good even better for our customers. One example is the use of artificial intelligence in this assembly and testing line for an innovative car lighting system, as told by our Head of Business Development Armin Braun.

Premium Quality thanks to Artificial Intelligence

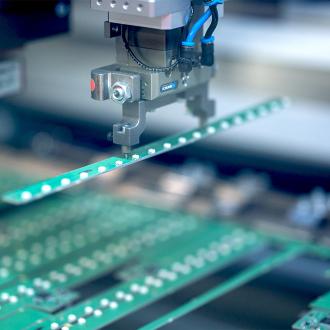

The Dynamic Light used in high-end models is a slightly different quality from other versions. A major challenge was to make sure that no particles are visible on the light band when it is active. Due to its multilayer setup with a top frame, optic fibers, and a diffusing panel, there is a high risk of particle contamination during production. To avoid this, we clean parts with ionized air during assembly to keep them as free of particles as possible. We specifically trained an AI module in the equipment to check this. The artificial intelligence detects each and every particle, no matter how small, to assess whether the strict quality requirements have been met.

We think of everything – including traceability

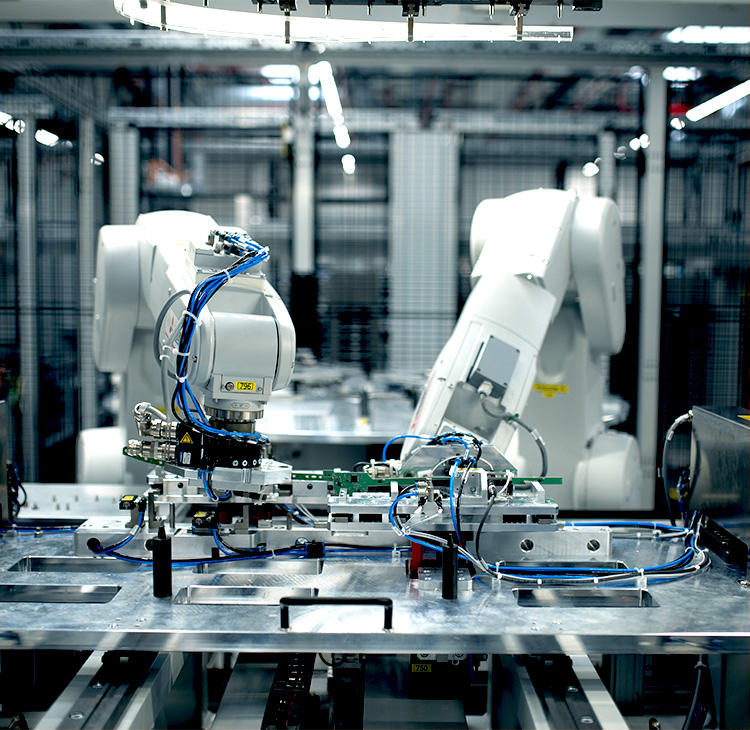

We develop as many parts and software components ourselves as possible. This makes implementation more efficient and generates benefits for our customers. For the Dynamic Light line, we developed the final inspection device, the software and the programmable logic controller (PLC) in-house. And we ensured maximum traceability to make absolutely sure that no light band that did not get perfect results on all 350 test criteria can slip through the cracks.

Essential measuring sequences and testing tasks:

- Particle check in optic fibers using artificial intelligence

- Communication test object

- Development of brightness adjustment for LEDs

- Measurement and adjustment of the LEDs’ color point: Assessment of product color by color space

- Analysis of multiple images from IP cameras

- Fully automated alignment of assessment points on the product position to compensate mechanical deviations in position

- Current measurements: bias current, operating current

- Check of product-side voltage measurement, inline and per batch

We think ahead and are always breaking new ground,

to offer our customers something special – discover more exciting reference systems!