SOLUTIONS FOR THE FUTURE

We have the necessary skills and we make it happen.

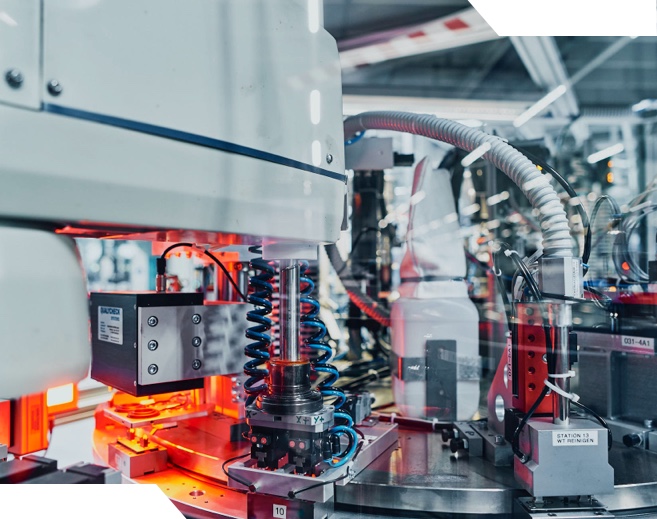

We put our heart and soul into every project, with great passion and a lot of know-how. No matter whether special engineering or testing technology – we’ve aligned ourselves with the biggest trends: Industry 4.0, process data capture, cyber security, traceability, robotics.

BEST SOLUTED

You set the requirements, we find the perfect solution. With our comprehensive technology portfolio - especially in the field of assembly applications, test and inspection automation - we offer you all common processes to realize systems that work reliably and with maximum efficiency. Are you looking for a specific area of expertise? Then click through our portfolio here:

SIMULATING PLANTS VIA DIGITAL TWIN

We build your system twice. Because before we physically pick up any component, we simulate your entire plant via digital twin using your customer product data and place it virtually in the original environment. This way, you can move around in your future plant in the planning stage using VR glasses, check its position in space, test gripping paths, replace parts and much more. This allows us to analyze process optimizations together with you before things get serious. With your feedback, we optimize system automation so that it functions perfectly after actual completion.

Fast, efficient and affordable.

SCALING AND CONVERTING PLANTS ASSEMBLY SYSTEMS

As a rule, you design your automated assembly lines for maximum quantities. But batch sizes are also subject to fluctuations depending on market developments. In order for you to react flexibly and always operate your systems economically, we make them scalable for you. Likewise, it must be possible for you to retrofit your system so that you can assemble and test many different types and products on it. For this, we develop appropriate, adaptable retrofit solutions based on special engineering.

DIGITALIZATION 4.0

In the age of Industry 4.0, digital networking of your assembly lines, testing technology, and infrastructure will be standard. This digitalization makes it possible for you and us to constantly monitor important status data and parameters automatically.

Traceability

Probably like many of our customers, you are paying increasing attention to ensuring that your quality products and their individual components are consistently traceable - Traceability from material storage to the finished component. When was what processed, assembled, and tested on which assembly line? Is a product that is the subject of a complaint an original or a fake? For traceability, it is important that products are given batch ID numbers, barcodes, serial numbers, or other means of identification. Together with you, we develop traceability concepts for process optimization that ensure full traceability. For us, this is not a book with seven seals, but everyday business.

Project Management in Real Time

For us, working together as partners and always communicating openly with you are the key to project success – in automating assembly systems and testing technology as well as in special engineering. For this reason, an experienced project manager from our team is available to you as a contact person throughout the entire duration of the project. Our goal is to provide real-time project management to relieve you as much as possible and to satisfy you in every respect. Accordingly, our project management acts like a responsible general contractor, holds all the strings and controls our interdisciplinary project team. For real-time project management, we use fully integrated, IT-supported planning and reporting tools. So that you know at all times how your project is progressing. Your advantage: maximum transparency and optimum planning and schedule reliability.

ACCREDITED HIGH-TECH TESTING LABORATORY

In our own accredited test laboratory for environmental and lifecycle tests, your products have to undergo various endurance tests - including long-term tests. This is how we ensure that your products function perfectly and in accordance with standards. For this purpose, we have high-tech testing technology such as a walk-in climatic chamber, transient test generators or computer tomographs at our disposal - in case you ever want to see the invisible in your product. For you, this means the certainty that we really do everything to ensure the quality you demand.

OTHER QUALIFICATIONS YOU BENEFIT FROM WITH MARQ4 AUTOMATION:

- Robotic (robot security, grippers, human-machine interface)

- Cyber Security

- Beckhoff and Siemens controllers

- Real-time project control in SAP

- Value stream analyses

CERTIFICATION

MARQ4 Automation works on the basis of a company-wide Quality Management System and is certified in accordance with ISO 9001:2015.